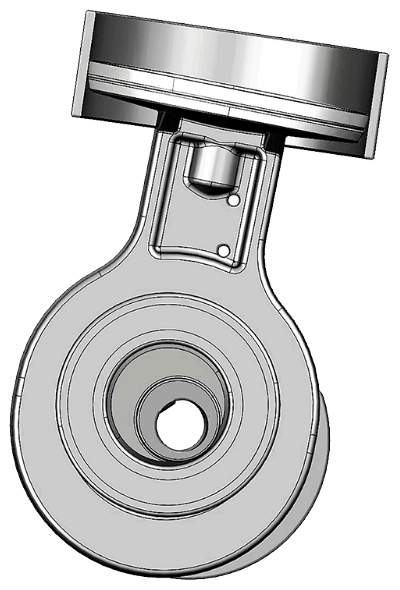

Unitary Piston / Wobble

Unitary Piston Technology (also known as Wobble) utilizes a monolithic, one-piece connecting rod and piston combined with a filled PFTE (Teflon™) seal and hard coat anodized thin walled aluminum cylinder sleeve. The piston seal is an inert, hydroscopic material and has an extremely low coefficient of friction compared with virtually all other solids.

Benefit to our customers:

- Proven Design – “The Internal Combustion Engine” of the Compressor and Vacuum Pump World

- Highly Configurable – Satisfies Many Diverse Applications

- Consistent Flow Performance Over Time (Rotary Vane and Articulated Piston Designs Lose Flow Over Time Due To Inherent Vane and Ring Wear)

- Durable – Long Service Free Life

- Highly Efficient PSC (AC) and Permanent Magnet (DC) Motors

- Light Weight

- Significantly Quieter Vs. Articulated Piston Technology

- Directly Replace Thomas® (WOB-L®), Gast® (ROC-R®), and Other Competitive Products

Compressors & Vacuum Pumps Using Unitary Piston / Wobble Technology:

Diaphragm

Diaphragm Technology utilizes a monolithic, one-piece connecting rod and rod pan combined with a nylon weave reinforced elastomeric membrane. Diaphragm Compressors and Vacuum Pumps are positive displacement devices and are best suited for pressure applications up to 30 PSIG and vacuum applications. Diaphragm technology is inherently gas tight which is the main reason it is chosen for vacuum applications. TruNorth’s compact, oil-less, diaphragm designs are ideal for Gas Sampling, Agriculture Foam Marking, Material Handling, Laboratory and many other applications.

Benefit to our customers:

- Proven Technology – Has Been Used By OEM’s For 100+ Years

- Consistent Flow Performance Over Time

- Durable – Long Service Free Life

- AC and Permanent Magnet DC Motor Options Available

- Light Weight

- Low Sound Level

- Directly Replace Thomas®, Gast®, and Other Competitive Products

Compressors & Vacuum Pumps Using Diaphragm Technology:

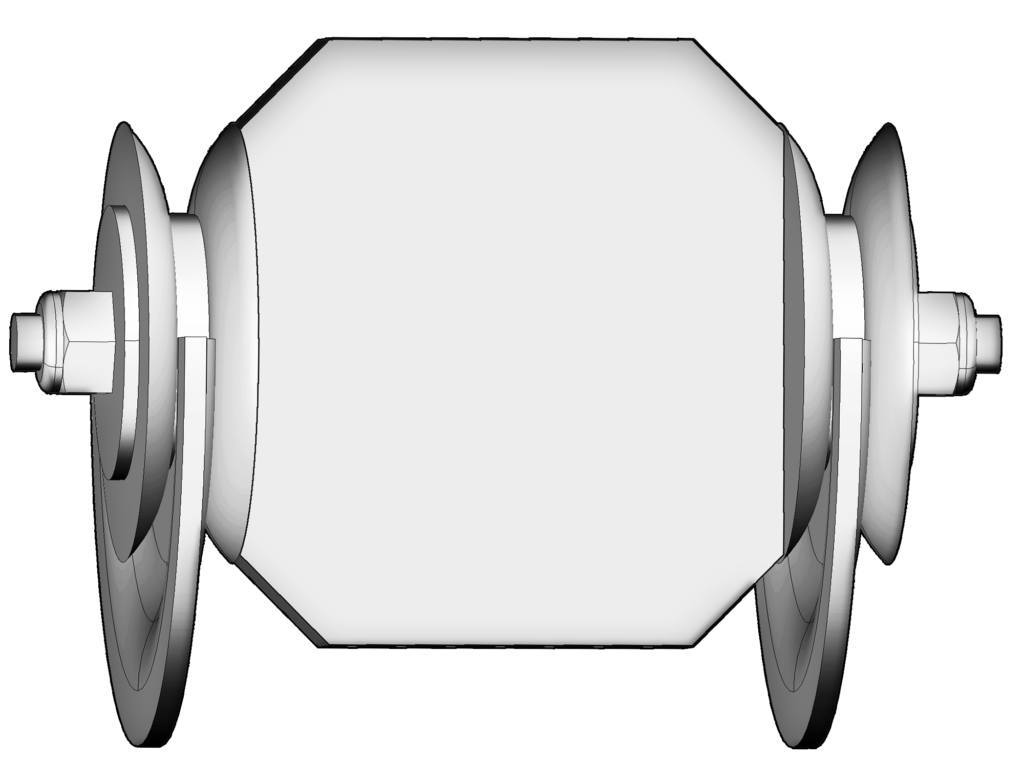

Linear Diaphragm

Linear Diaphragm Technology utilizes an electromechanically driven shuttle with elastomeric diaphragms affixed to both ends. This proven technology has been in use for 50+ years and is virtually maintenance free. Linear technology uses a natural resonance which assists the electric drive coil resulting in a highly efficient, low power consumption device. Linear Diaphragm Compressors and Vacuum Pumps are nonpositive displacement devices and are best suited for low pressure and vacuum applications. TruNorth’s compact, oil-less, linear diaphragm designs are ideal for Air Mattress, DVT Compression Therapy, Acute Care Minimum Air-loss Beds, Autoclave, Fish Tank Aeration, Gas Sampling and many other applications.

Benefit to our customers:

- Virtually No Maintenance Cost

- Consistent Flow Performance Over Time

- Long Service Free Life, No Ball Bearings

- Light Weight

- Very Low Sound Level

- Directly Replace Thomas®, Gast®, and Other Competitive Products

Designed, Machined & Assembled in America

Designed, Machined & Assembled in America