In food and beverage processing, compressed air often comes into direct or indirect contact with products. Whether it’s used for packaging, conveying, filling, or cleaning, the quality of that air has a direct impact on food safety, shelf life, and regulatory compliance. That’s why selecting the right food-grade oil-less compressors is critical for manufacturers who want to protect their products and their brand.

Not all oil-less compressors are created equal. Beyond the absence of lubrication, food-grade systems must meet specific certifications, incorporate contamination-prevention features, and consistently deliver clean air. Below, we’ll break down the most important standards, safety considerations, and performance factors to evaluate when comparing food-grade oil-less compressors.

Why Oil-Less Matters in Food Applications

Traditional oil-lubricated compressors pose a contamination risk if oil aerosols migrate into the compressed air stream. Even trace amounts can compromise food safety, trigger recalls, or violate regulatory requirements. Oil-less compressors eliminate this risk at the source by removing oil from the compression process entirely.

For food processors, this means cleaner production environments, fewer filtration stages, and greater confidence that compressed air will not introduce contaminants into packaging lines or processing equipment.

Required Certifications and Standards

When evaluating food-grade oil-less compressors, certifications are often the first indicator of suitability. These standards ensure equipment meets safety, hygiene, and quality requirements across the food supply chain.

FDA Compliance

The U.S. Food and Drug Administration (FDA) sets guidelines for materials and components that may come into contact with food. While compressors themselves are not always in direct contact, FDA-compliant materials help ensure that any incidental exposure does not pose a risk.

ISO Standards

ISO certifications, particularly ISO 8573-1 for compressed air quality, define acceptable levels of particles, moisture, and oil content. For food-grade applications, oil-less compressors are typically selected to meet the highest air purity classes.

HACCP (Hazard Analysis and Critical Control Points)

HACCP is a preventive approach to food safety that identifies and controls potential hazards. Using oil-less compressors supports HACCP plans by removing oil contamination as a potential critical control point.

NSF Certification

NSF standards focus on public health and safety in food equipment. Compressors or components certified by NSF demonstrate that they meet stringent hygiene and material safety requirements, particularly in food-contact environments.

Safety Features That Prevent Contamination

Beyond certifications, design features play a major role in maintaining food safety. High-quality food-grade oil-less compressors include multiple layers of protection to ensure clean operation:

- Oil-free compression chambers

- Sealed bearings and internal components

- Integrated particulate and moisture filtration

- Condensation and humidity control systems

These features are especially important in high-humidity food processing environments where moisture can encourage microbial growth.

The Importance of Clean Air in Food Packaging

In food packaging, compressed air is often used to form packages, remove oxygen, or maintain pressure during sealing. Any contamination introduced at this stage can shorten shelf life or compromise product safety.

Clean air supports:

- Modified Atmosphere Packaging (MAP)

- Vacuum sealing applications

- Consistent product appearance and integrity

Oil-less compressors ensure these processes remain hygienic and compliant.

Long-Term Operational Benefits

Food-grade oil-less compressors offer more than compliance—they deliver operational advantages over time:

- Reduced filtration and maintenance costs

- Improved uptime and reliability

- Easier audits and food safety documentation

- Lower risk of recalls or contamination events

These benefits make oil-less systems a strategic investment rather than just a regulatory requirement.

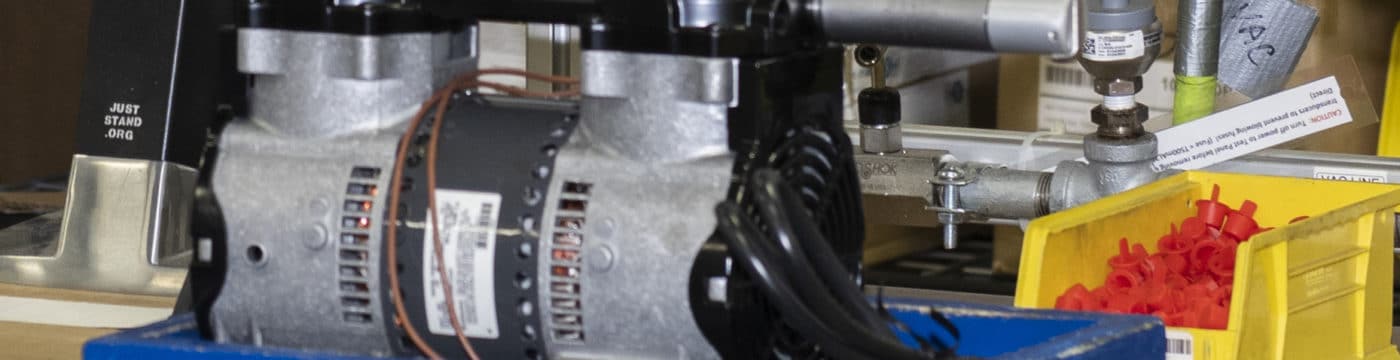

Working With the Right Supplier

Choosing the right compressor also means choosing a supplier who understands food-grade applications. TruNorth Components provides food-grade oil-less compressors designed for clean operation, regulatory alignment, and long-term reliability.

By supporting food processors and OEMs with engineered solutions, TruNorth Components helps ensure compressed air systems meet today’s standards—and tomorrow’s expectations. With a range of oil-less compressors designed specifically for food-grade applications, TruNorth Components offers the expertise and support needed to maintain a safe and efficient facility.

Final Thoughts

When comparing food-grade oil-less compressors, certifications like FDA, ISO, HACCP, and NSF form the foundation of safe operation. Combined with thoughtful design and clean air performance, oil-less technology protects food quality, extends shelf life, and simplifies compliance.

For manufacturers committed to food safety and operational excellence, oil-less compressors are no longer optional—they are essential.

Designed, Machined & Assembled in America

Designed, Machined & Assembled in America